Product Category

Telephone:

Email:

Address:

No.5, Zhaozhuang Industrial Park, Liu Changshan Road, Shizhong District, Jinan City

Efficient and flexible: widely used in industrial and civil construction and other small hole deep pile scenes, the main hoist up and down fast, high hole verticality, widely used in the field of industrial and civil construction, high construction efficiency. Special chassis: specially designed for rotary excavation telescopic wide chassis, roller type large diameter slewing bearing, to meet the high stability of deep hole construction.

Efficient and flexible: widely used in industrial and civil construction and other small hole deep pile scenes, the main hoist up and down fast, high hole verticality, widely used in the field of industrial and civil construction, high construction efficiency. Special chassis: specially designed for rotary excavation telescopic wide chassis, roller type large diameter slewing bearing, to meet the high stability of deep hole construction.

Mast height: 30.5 m Power head model: KDK390S Power head torque: 390KNm

Name: Germany BG 30 special rotary drilling rig (BT 80 main engine) Model BG 30 Host model BT 80 Overall height (m) 26.9

Name: Germany BG 26 special rotary drilling rig (BT 70 main engine) Model BG 26 Host model BT 70 Overall height (m) 25.1

Model BG25(BT70 mainframe) Mast height: 22.8 m Power head model: KDK245K Power head maximum torque: 237KNm

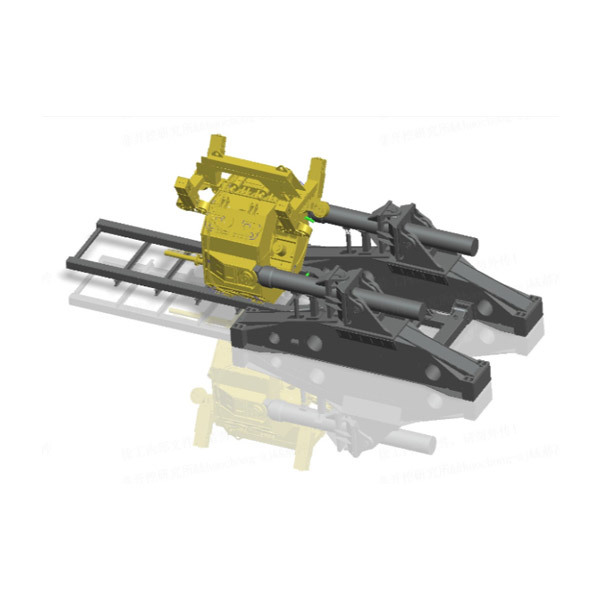

XCMG horizontal directional drilling rig

1. The digital display system directly displays the main construction parameters such as rotating torque, pushing and pulling force, overcoming the shortcomings of the traditional drilling rig using pressure gauges that need to be converted, and the operation is simple; 2. Dual power system, any engine can complete all the actions of the drilling rig when starting, combined with proprietary multi-condition speed control technology and rotation, push-pull multi-gear control technology, the drilling rig has a wide range of applications, in the case of small aperture construction, can Use an engine to work, low fuel consumption and low construction cost;

XCMG horizontal directional drilling rig

1. The digital instrument can automatically display the actual torque, pushing and pulling force and other construction main parameters in the construction, and the operation is simple; the electronic sensing technology is sensitive, can timely feedback the instantaneous overload, and reliably protect the drilling rig; 2. Dual power system, any engine can complete all the actions of the drilling rig when starting, combined with proprietary multi-condition speed control technology and rotation, push-pull multi-gear control technology, the drilling rig has a wide range of applications, in the case of small aperture construction, can Use an engine to work, low fuel consumption and low construction cost;

XCMG horizontal directional drilling rig

1. The digital instrument can automatically display the actual torque, pushing and pulling force and other construction main parameters in the construction, and the operation is simple; the electronic sensing technology is sensitive, can timely feedback the instantaneous overload, and reliably protect the drilling rig; 2, PE pipeline elastic balance release technology, effectively prevent the equipment damage caused by the back drag pipeline reaction force, improve the reliability of equipment construction;

XCMG horizontal directional drilling rig

1, high and low speed push and pull rotation system, plunger variable motor to achieve power head push and pull high and low speed, increase the rig working condition adaptability, improve construction efficiency; 2. Push-pull and rotation adopt multi-gear output technology, engine high-pressure common rail, full electronic control module technology, system energy saving and efficient construction;

Gutton Horizontal Directional Drill

Product Introduction of Gutton Mechanical GS3000-L/LS Horizontal Directional Drill 1. Hydraulic system: push-pull, rotation, walking with closed system, electro-hydraulic proportional control; 2. Configure dual-power system to meet the needs of different working conditions, and can flexibly realize dual-machine work or single-machine work, saving energy and reducing consumption; when a hydraulic system or engine fails, the other system can work normally (the power remains unchanged, The speed slows down, and the drilling rig has no function loss), which greatly improves the safety of construction; 3. The front and rear clamps can be separated, and the gripper floats in the whole process; 4. The main shaft floating, is conducive to the protection of drill pipe screw; 5 Floating girder is conducive to climbing and transportation, and it is also convenient to adjust the incident angle; 6. Proportional line control walking system to ensure the safety of man-machine in the process of walking, loading and unloading; 7. Electric control handle, simple circuit, safe and reliable, high sensitivity; 8. Car cab space wide, adjustable seat, more human, more comfortable 9. In order to improve the operation capacity of the equipment, the hydraulic system adopts a large flow and high pressure design, and is equipped with a cartridge control valve group independently designed by Gutton Machinery. The system responds quickly and the system pressure loss can be reduced by about 50%. 10. The self-designed and developed electro-hydraulic joint control system realizes the adaptive control of the main engine under different working conditions and different geology, which can improve the construction efficiency of the main engine by about 30%; the system is equipped with two modes of automatic operation and manual operation. In the automatic operation state, the operating parameters of the drilling rig are adjusted in time according to the geological conditions, and the drilling rig is automatically adjusted to achieve the purpose of protecting the safety of the drilling rig; 12. Reasonable and effective flushing and cooling system ensures the reliability and efficiency of system operation; avoids motor damage and prolongs service life. Main parameters Whole machine quality 46t Overall dimension 16600x2950x3400 Maximum push-pull force 3000kn Other parameters Maximum torque 100000N.m Maximum push-pull speed 35m/min

Gutton Horizontal Directional Drill

Introduction of Guden Machinery GS1600-L Horizontal Directional Drilling Products 1. The high quality power system Weichai turbocharged engine has strong power, stable performance, and fuel consumption lower than other engines by more than 20%. 2. The reliable and stable hydraulic system is equipped with imported electric proportional motors. The gear transmission structure is simple, the performance is reliable, and the push-pull is stepless. Variable speed, push-pull force can reach 1,700kN, and the work efficiency is industry-leading. 3. The chassis walking device adopts international famous brand two-speed motor, with a walking speed of up to 6 km/h, and no loading is required for short-distance transition. 4. The center of the holder is low, which not only protects the drill pipe efficiently, but also occupies less space for construction. The front and rear clamps can be separated and can be replaced according to the drill pipe specifications. 5. The unique power head structure designs the main shaft to float, which is beneficial to protect the drill pipe screw. 6. The four-link luffing mechanism has a large angular range (10 ° ~ 22), low center of gravity of the drilling rig and good stability. 7. Stable walking system Proportional line-controlled walking system ensures the safety of equipment and personnel. It is convenient and quick for drilling rig to walk, transfer and loading and unloading. 8. Three degrees of freedom high-end rotating manipulator. Gu Deng rotating manipulator, to achieve automatic unloading rod, safe and convenient, greatly reduce the operating cost. 10. The LCD large screen human-computer interaction system can monitor and adjust the equipment status in real time, making the operation easier and more comfortable. 11. The automatic drilling control system is equipped with automatic and manual operation modes. Under the automatic operation state, the operating parameters of the drilling rig can be adjusted in time according to the geological conditions, so as to achieve the purpose of protecting the drilling rig. Main parameters Whole machine quality 29000 kg Overall dimension 11280*2870*2850(mm) Maximum push-pull force 1700 kN Other parameters Maximum torque 78000 N·m Maximum push-pull speed 47 m/min Maximum slewing speed 101 r/min Engine power 316kW

Gutton Horizontal Directional Drill

Introduction of Guden Machinery GS1000-L Horizontal Directional Drilling Products 1. Cummins turbocharged engine has strong power, stable performance and lower fuel consumption than other engines. 2. Push-pull device is equipped with German Rexroth motor, with simple transmission structure and reliable performance. Push-pull multi-stage speed change, push-pull force increase can reach 1470kN, leading in work efficiency and speed industry. 3. Rotary configuration of French Porkland high-pressure plunger motor, rotary multi-stage speed change, greatly improving work efficiency: 4, the walking speed is up to 5 km/h, and there is no need to load for short-distance transfer. 5. The center of the clamp is low, which not only protects the drill pipe efficiently, but also takes up less space for construction. The front and rear clamps can be separated, and the corresponding clamp blocks can be replaced according to the drill pipe specifications. 6. The main shaft floats, which is beneficial to protect the drill pipe thread. 7. The four-link luffing mechanism is adopted, with large angle range (10~19, good stability; 8. Proportional wire-controlled walking system ensures the safety of equipment and personnel. Drilling rig walking, transfer and loading and unloading are convenient and quick. 9. Gu Deng's patented rotating manipulator automatically slides down the drill pipe without manual unloading, thus saving labor costs. 10. The on-board operation room is large in space, rotatable and equipped with cold and warm air conditioning. 11. The LCD human-computer interaction system can monitor and adjust the equipment status in real time, making the operation easier and more comfortable; 12. The system is equipped with automatic and manual operation modes. Under the automatic operation state, the operating parameters of the drilling rig can be adjusted in time according to the geological conditions, so as to achieve the purpose of protecting the drilling rig. Main parameters Overall dimension 11085X2365X2610 Maximum push-pull force 1000/1500 (force) kN Maximum torque 45000 N-m Maximum push-pull speed 39m/min Maximum slewing speed 110 r/min Engine power 264KW crawler travel speed 3-5km/h

Mud pump suction protection/overpressure protection system Improve mud pump life and ease of maintenance Main engine joint control system of mud pump

1. The stroke of the propulsion cylinder is long, and a drill pipe only needs to go back and forth 3 times 2. Large jacking force, retraction force and clamping force 3. Fast jacking and retraction speed, high construction efficiency

XDC Series Tubing Machine (Well-forming Equipment)

1. The driving torque is large, the tube rubbing efficiency is high, and the immersed tube depth can reach 15m. 2. Independent lifting and lifting cylinder, taking into account pipe pressing and pipe pulling operations.

XDL500 Spiral Pipe Jacking Machine

1. Guided drilling is equipped with image monitoring system, and the horizontal straightness of the whole jacking process is ± 25mm. 2. Low requirements for operator skills, small equipment, strong power, fast jacking speed, effectively reducing construction costs and improving construction efficiency;

XDT Series Rectangular Pipe Jacking Machine

Size customized according to customers!!! Note: This product is constantly improved with technological progress, the above listed parameters and structural characteristics and physical differences in kind shall prevail.