Product Category

Telephone:

Email:

Address:

No.5, Zhaozhuang Industrial Park, Liu Changshan Road, Shizhong District, Jinan City

Shanhe intelligent rotary drilling rig

Performance Characteristics of Shanhe Intelligent SWDM360H Rotary Drilling Rig 1. Special chassis Special hydraulic telescopic chassis for rotary excavation, the main and auxiliary winches are arranged on the platform, with good stability. 2. Auxiliary legs Auxiliary legs on the lower mast can provide auxiliary support, lower casing and rig maintenance. 3. Convenient transit transportation Parallelogram luffing mechanism, back-to-back mast transportation, transfer convenient and fast. 4. High configuration The torque of the power head reaches 418 kN.m, and the rock-entering ability is strong. Remove the lower mast, the maximum drilling diameter can reach 3000mm Parameters SWDM360H III Overall dimension (length×width×height) Working status 10435 × 4800 × 27190 mm Transport status 20160 × 3400 × 3600 mm Overall machine height 27190mm Whole machine weight 123t Maximum drilling diameter 2500mm(3000mm) Maximum drilling depth 102m/66m Engine Brand Cummins Model QSX15-C535 Power 399kW/2100rpm Power head Maximum torque 418kN.m Speed 6 to 25rpm High-speed soil throwing (optional) -- Pressurized system Maximum pressure 340kN Maximum lifting force 380kN Maximum travel 13000mm Master Wink Maximum lifting force 370kN Maximum lifting speed 80m/min Vice winch Maximum lifting force 110kN Maximum lifting speed 65m/min drill mast Left and right inclination ± 4 ° anteversion angle 5 ° Chassis Crawler width 900mm Telescopic width of crawler 3300~4800mm Chassis length 6120mm

Shanhe intelligent rotary drilling rig

SWDM280 medium-sized multifunctional rotary drilling rig has large main hoisting force, fast speed, key shaking function, saving drilling auxiliary time and high comprehensive construction efficiency.

Shanhe intelligent rotary drilling rig

Performance Characteristics of Sunhe Intelligent SWDM220 Rotary Drilling Rig 1. Super durable and reliable bearing The drilling reaction force of the rotary drilling rig is transmitted from the drilling tool to the machine, and then from the machine to the ground. Each structural part of the machine bears the structural stress caused by the drilling force. 1) Dedicated chassis ● The self-developed special telescopic structure chassis suitable for the actual working condition load of rotary excavation is adopted. The whole machine has high stability and can realize 360-degree arbitrary construction, which is more conducive to the structural parts of the whole machine and ensures the balance of the center of gravity. 2) Rolling arrangement ● The main and auxiliary winch is installed on the platform, which greatly reduces the rotary inertia of the upper part of the platform and the tilting moment of the working device, and improves the stability of the whole machine. 3) Square shaft box structure ●The mast deflection seat adopts a box-type square shaft box structure, which directly transmits the force of the mast to the luffing mechanism, eliminating the force exerted by the rotary drilling force on the weak link of the deflection seat, and improving the structural stability and reliability. 4) Drill mast structure ● The drill mast adopts high-strength anti-deformation design, and the rectangular mast section is wider in the guide rail direction, which effectively reduces the structural stress of the mast and can better adapt to the rock-entering construction conditions of high-strength dynamic load. 5) luffing mechanism ● The parallelogram adjustment mechanism adopts wide-width design, with large structural size (I. e., large M size) and large installation distance between the two drill mast luffing cylinders (I. e., large W size), which is equivalent to a large triangular structure. During hard formation construction, the stability of the working device is better. 2. High configuration Efficient and reliable engine matching high-power hydraulic transmission system is a powerful guarantee for strong machine power. The advanced intelligent electronic control system can give full play to the machine efficiency, and the reasonable local structure design can greatly reduce the vulnerability and consumption. 1) Engine ● Using Cummins EFI turbocharged intercooled engine, with high reliability, fuel economy and high efficiency reserve power. Emissions in line with the European EPAC3 standards, green environmental protection, in high cold, high altitude areas can still operate normally. 2) Hydraulic components ● The hydraulic system developed in cooperation with the world-flow component supplier improves the hydraulic energy conversion rate of the component and reduces the pipeline transmission loss of the system. 3) Multi-mode power head to achieve efficient drilling in different formations ● According to different geological conditions, the power output mode matching the load can be selected to make the construction process more efficient and energy-saving. 3. Low Cost 1) Roll Jane ● According to the construction characteristics of rotary excavation main hoisting, the main hoisting device is innovatively designed. Through the design of two layers of rope carrying grooves in the inner and outer steps of the drum, the rope grinding section most frequently used in rotary excavation is effectively protected, and the use of wire ropes The service life is extended by more than 100%. 2) Self-loading and self-unloading of counterweight. ● Can use its own mast disassembly, assembly weight, no need to be equipped with other lifting equipment, saving the cost of auxiliary equipment. 3) Power matching, fuel saving and high efficiency ● The engine-hydraulic system-load global power is perfectly matched, and the hole forming efficiency is increased by 10%-25%; The hydraulic system is optimized to reduce the overflow loss, throttling loss and pressure loss along the system and save fuel consumption by 7%-20%. 4. Intelligent control easy driving Advanced intelligent control system, give full play to the performance of the equipment, while making the operation easy. 1) Safety protection measures ● Shanhe intelligent rotary drilling rig fully consider the safety guarantee, in the construction process rest assured. The cab adopts a special-shaped frame structure, and the front and top are equipped with high-strength plate frame protective covers to provide maximum protection for the safety of the operator. 2) Auxiliary legs ● The legs hidden under the mast can not only provide auxiliary support for drilling construction, but also accomplish some unexpected things. 3) handle self-locking function ● Proprietary electromagnetic locking handle,-key to achieve handle positioning, get rid of heavy physical labor. 4)GPS remote service ● Using GPS. GIS. 2G/3G mobile communication technology, a remote operation and maintenance, monitoring and fleet cooperative operation control platform for rotary drilling rigs is constructed. 5. Multi-functional expansion of high-value embodiment Shanhe intelligent rotary drilling rig has a variety of configurations for you to choose from, to achieve-machine multi-function, diversified construction. 1) Pipe rubbing machine method ● The main engine can be equipped with an external oil source interface for the construction of the pipe rubbing machine, and the pipe rubbing machine construction method is adopted to effectively solve the problem of easy collapse in the construction of the stratum such as quicksand, silt and backfill soil. 2) Simplified driver protection method ● Rotary drilling rig equipped with simple protection driver construction can effectively and quickly buried simple protection, in the backfill soil layer, shallow sand pebble layer, multi-cave limestone layer can play an obvious advantage. The selection of the casing driver can ensure the verticality of the casing and effectively prevent the collapse. The drilling rig and the casing can be carried out at the same time to improve the efficiency of the drilling rig. 3)CFA long auger drilling method ● CFA long spiral drilling rig method can realize continuous drilling pile and grouting. It is a new type of composite foundation treatment method with high construction efficiency, especially for small holes, dry holes and shallow holes. 4) High-speed soil throwing power head ● The power head with high-speed soil throwing function can be configured, and the soil throwing speed can reach 70rpm to realize the high-speed soil throwing function.

Shanhe intelligent rotary drilling rig

SWDM160H medium-sized multifunctional rotary drilling rig has large main hoisting force, fast speed, key shaking function, saving drilling auxiliary time and high comprehensive construction efficiency.

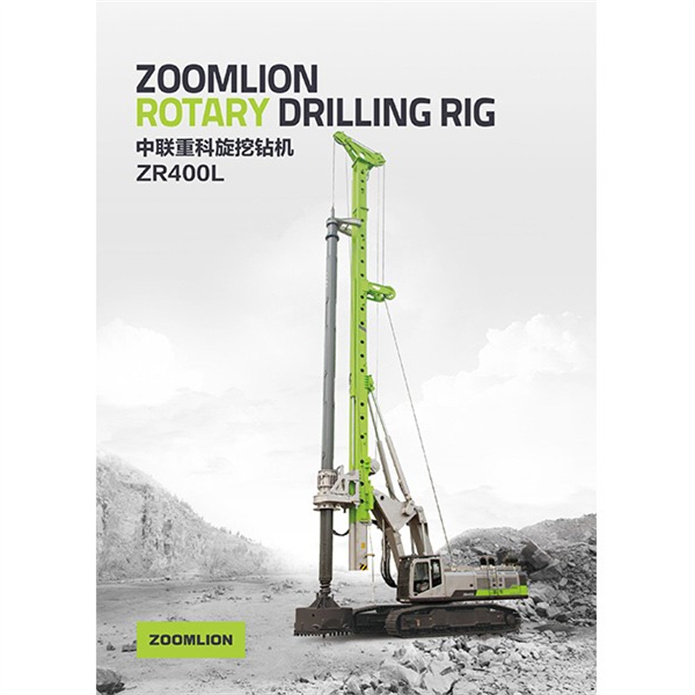

Zoomlian Heavy Industry Rotary Drilling Rig

ZOOPLAN ZR400L Rotary Drilling Rig Product Performance Characteristics 1. Strong rock entering ability: 580 drill pipe is standard, the maximum torque is up to 430kNm, the maximum drilling diameter is 3000mm, and the hard rock depth of 5-section machine lock rod can reach 91m. 2. High stability: adopting eccentric rotary reducer and advanced positioning and assembly technology, the rotary clearance is reduced by 70%; The chassis manufacturing process is upgraded to reduce the expansion clearance by 60%, effectively improving the stability at work; 3. Easy to use: parallelogram structure is adopted, and the transportation height without dismantling the crawler is 3715mm, which is convenient for transportation. 4. Comfortable operation: 12.3-inch capacitive touch screen is configured to realize three-dimensional dynamic display of the whole machine, with high brightness and no visual delay. With the compact control panel, the operation steps are reduced by 30%. 5. Intelligent control: The bottom protection function is upgraded, and the speed is automatically reduced when approaching the bottom of the hole, reducing the impact of the whole machine and the hoisting system, and effectively protecting the wire rope. regular parameters Equipment Model ZR400L Model abbreviation 400 Engine Model Cummins QSX15 Rated power (kW) 398 Displacement (L) 15 Whole machine parameters Total mass of equipment (kg) 130000 Overall dimension (working state)(mm) 10125 × 5000 × 27430 Overall dimension (transportation state)(mm) 19886 × 5000 × 3715 Output torque of power head (kN · m) 430 Power head speed (r/min) 4 to 24 Maximum drilling depth (mm) 110000/91000 Drilling diameter (without casing)(mm) 3000 Traction force (kN) 600 Distance from swing center to tail of main engine (mm) 4845 Mast height (m) 27.4 Chassis parameters Maximum travel speed (km/h) 1.8 Track width (mm) 900 Pressurizing cylinder Maximum pull-out force (kN) 400/400 Maximum pressure (kN) 340/360 Pressurizing cylinder stroke (mm) 6000/16000 Master Wink Main winch Single-layer one-tube double machine Maximum lifting force (kN) 415 Max. hoisting speed (m/min) 75 Diameter of wire rope (mm) 40 Vice winch Maximum lifting force (kN) 90 Max. hoisting speed (m/min) 70 Diameter of wire rope (mm) 22 Mast inclination Sideways (°) 3.5 Forward (°) 4 Tilt backward (°) 90

Zoomlian Heavy Industry Rotary Drilling Rig

ZR280C is a Zhonglian 280KN rotary drilling rig. It can be equipped with power head casing driver and pipe rubbing machine, which is especially suitable for construction conditions such as sandy pebble layer, backfill soil, karst geology and rich groundwater formation.

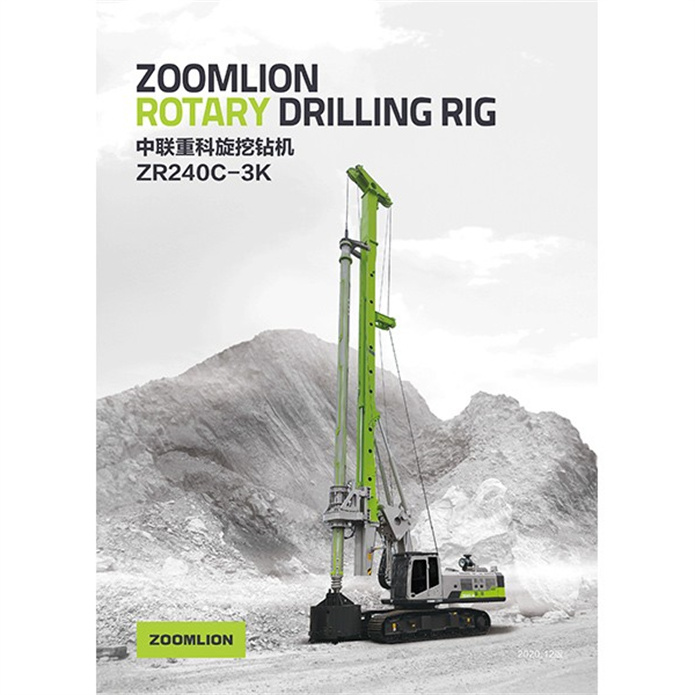

Zoomlian Heavy Industry Rotary Drilling Rig

Zoomlion ZR240C-3K Rotary Drilling Rig Product Introduction 1. One-key folding of the hanging anchor frame, no removal of mast support, convenient and quick transition. 2.2.0 version of power matching and limit load control technology, work efficiency increased by 10%. 3. The use of large-flow main pump, multi-gear power head, two-speed pressurized oil cylinder, the construction efficiency is higher. 4. The central single-row main winches and one-tube double machines have stronger lifting capacity; single-layer wire rope, **to maximize the service life of the wire rope. 5. Double rotary speed reducer, increase the parking torque, rock drilling operation rotary lock does not shake. 6.**V generation power head, large angle eave rod cylinder support, low center of gravity, reinforced chassis, make the machine structure more stable, stronger bearing. 7. Adopt a new generation of cab, full man-machine interface, good sight, more comfortable operation. 8. A new generation of electronic control platform, 360-degree full-view monitoring, mobile phone APP push device information, safe and convenient. Main parameters Unit Numerical Remarks Borehole parameters Max. large drilling diameter mm 2000 Maximum drilling depth m 70/56 Friction rod/engine lock rod 60/48 Optional Power head Maximum output torque kN.m 260 Speed range rpm 6-26 Pressurized system Pressurization mode Pressurizing cylinder/(winched and pressurized) Add pressure kN 220/(255) Pulling force kN 230(255) Maximum Pressurization Stroke mm 5300/(15000) Master Wink Structure type of drum Single layer, one barrel double machine Maximum single rope pull kN 240 Maximum speed m/min 70 Wire rope diameter mm 32 Vice winch Maximum single rope pull kN 90 Maximum speed m/min 80 Wire rope diameter mm 22 Mast Inclination Front/Rear ° 5/90 Left/Right ° ± 4.5 Engine Engine Model Cummins QSL9 Engine rated power kW 242 Engine emission standards Country III Engine Displacement L 8.9 Chassis Track outer width (min ~ max) mm 3260-4400 Telescopic chassis Track shoe width mm 800 Tail turning radius mm 4036 complete machine Quality of work t 80 Maximum traction kN 423 Maximum travel speed km/h 2.26 Overall machine height m 23.3(21.3) Configurable Drill Pipe Models Model Drilling depth m Remarks Friction bar Φ440-5 × 15.5m 70 Locking bar Φ440-4 × 15.5m 56 Standard Friction bar Φ440-5 × 13.5m 60 Locking bar Φ440-4 × 13.5m 48

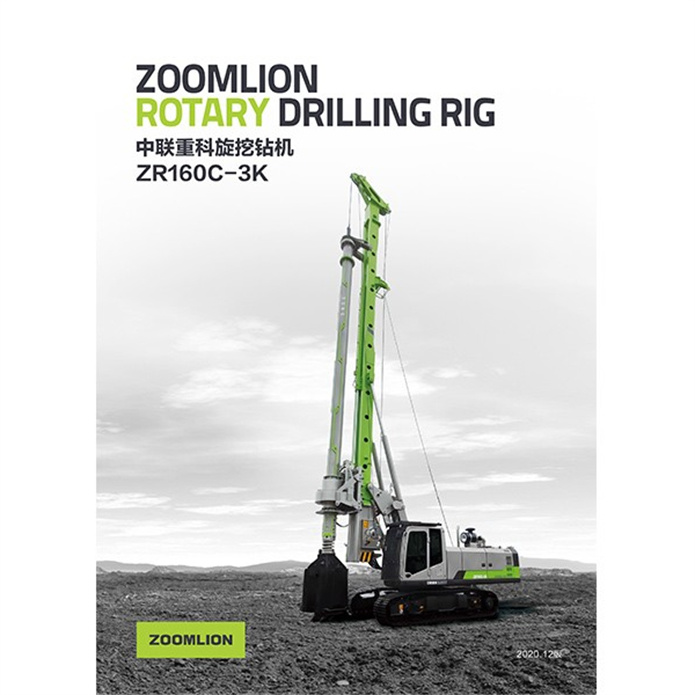

Zoomlian Heavy Industry Rotary Drilling Rig

Performance Characteristics of Zoomlian Heavy ZR160C-3K Rotary Drilling Rig 1. The whole vehicle can be transported with rods, and the work and transition can be quickly changed. A single assembly and disassembly can save 4 hours. 2. A flatbed truck can realize the whole machine transportation, and the single transfer cost is 30% lower than that of the same model in the industry. 3. The power head has large torque, high reserve coefficient and stronger application capacity. 4. The high speed of the power head * * can reach 45rpm, and the soil rejection efficiency is 10% higher than that of competing products. 5. The use of large-flow main pump, multi-gear power head, two-speed pressurized oil cylinder, higher efficiency. 6. Large mast section, low center of gravity of the whole machine, large diameter slewing bearing and reinforced chassis make the machine structure more stable and strong bearing. 7. Adopt a new generation of cab, new man-machine interface, good sight, more comfortable operation. 8. A new generation of electronic control platform, 360-degree full-view monitoring, mobile phone APP push device information, safe and convenient. 9. The selection industry pioneered wireless control to realize remote control walking, car exhibition and car collection functions. Main parameters Unit Numerical Remarks Borehole parameters **Large drilling diameter mm 1500 **Large drilling depth m 56/44 Friction rod/engine lock rod 62 Optional Power head **Large output torque kN.m 180 Speed range rpm 5 to 33 Standard 5 to 45 Optional Pressurized system Pressurization mode Oil cylinder pressurization Add pressure kN 160 Pulling force kN 160 **Large Pressurization Stroke mm 4500 Master Wink Structure type of drum double layer **Large single rope pull kN 170 **Great speed m/min 73 Wire rope diameter mm 26 Vice winch **Large single rope pull kN 60 **Great speed m/min 80 Wire rope diameter mm 18 Mast Inclination Front/Rear ° 5/90 Left/Right ° ± 3.5 Engine Engine Model Cummins QSC8.3 Engine rated power kW/rpm 181/2000 Engine emission standards Country III Engine Displacement L 8.3 Chassis Outer width of crawler (**small ~** large) mm 3000~4000 Track shoe width mm 700 Tail turning radius mm 3950 complete machine Quality of work t 54 **Large traction kN 330 **Large walking speed km/h 2.1 Overall machine height m 18.8/(20.3) Whether to transport with rod Yes Transport height with rod mm 3588

XCMG XR460E rotary drilling rig performance characteristics: 1. The telescopic crawler chassis with swing legs is adopted to meet the stability of large-tonnage drilling rigs and the convenience of disassembly and transportation. It is equipped with large-diameter slewing bearings and has stronger anti-overturning ability; 2. The power head adopts vertical pin connection type power box body and bracket, which has high reliability and convenient disassembly and assembly; 3. The power head has normal mode, rock entry mode, medium speed rock entry mode and energy saving mode. Users can choose corresponding modes according to different geological conditions, which improves construction efficiency and reduces fuel consumption; 4, the main hoist using single row rope technology, wire rope life than multi-layer rope 2 to 4 times longer, the use of lower cost; 5. The hydraulic main and auxiliary systems adopt load-sensitive control technology, which has fast response and good handling performance. It adopts a double overhead heat dissipation system, which intelligently adjusts the heat dissipation capacity according to the temperature, with strong heat dissipation capacity, energy saving and noise reduction; 6. Equipped with Cummins 15L electronically controlled turbocharged engine, strong power, low fuel consumption, convenient and quick service, decentralized independent heat dissipation system, strong heat dissipation capacity and low noise. Project Unit Parameters Maximum drilling diameter (mm) φ3000 Maximum drilling depth (m) 106 Working state drilling rig size length * width * height (mm) 11470 × 5100 × 27720 Transportation status Rig size length * width * height (mm) 19156 × 3700 × 4000 Overall machine quality (excluding drilling tools under standard configuration) (t) 135 Hydraulic system Maximum working pressure (Mpa) 33 Power head Maximum torque (kN.m) 460 Drilling speed (r/min) 6-25 Engine power KW 447 Pressurizing cylinder Maximum pressure (kN) 350 Maximum lifting force of pressure cylinder (kN) 400 Travel (mm) 6000 Walk. Maximum travel speed of the whole machine (km/h) 1.3 Master Wink Maximum lifting force of main hoist (kN) 450 Main Hoisting Maximum Single Rope Speed (m/min) 70 Vice winch Maximum lifting force of auxiliary winches (kN) 110 Maximum single rope speed (m/min) 50 drill mast Mast Left/Right Inclination (°) ± 4 Mast forward inclination (°) 5 Turret rotation Turntable rotation angle (°) 360 Crawler Track shoe width (mm) 900 Outer width of crawler (mm) 3700~5100 Maximum climbing degree of the whole machine (%) 35

XCMG XR400E rotary drilling rig performance characteristics: 1. Optimize the design of the double-boom luffing mechanism, optimize the position of the hinge point, and take into account the stability of construction and the convenience of transfer transportation; 2, the use of rotary drilling rig dedicated H-type hydraulic telescopic crawler chassis, equipped with large diameter slewing bearings, to ensure a strong stability and transportation convenience; 3. Imported Cummins engine is adopted with strong power and three-speed power control. Users can select corresponding gears according to working conditions to realize the function of three engines in one drilling rig. Optimized three-speed power curve. Load sensing technology is adopted for the hydraulic system, and total power control and limit power control technology are superimposed to make the hydraulic system more efficient and energy-saving. The three-in-one radiator system is adopted with compact structure and high heat dissipation efficiency; 5. XCMG's proprietary single-row rope main hoisting structure effectively solves the problem of wire rope "biting rope" and greatly prolongs the service life of wire rope; 6, the power head has a normal mode, into the rock mode and energy-saving mode, the user can choose the corresponding mode according to different geological conditions, improve the construction efficiency and reduce fuel consumption; 7. Multiple configurations: optional winch pressurization, chassis leg oil cylinder, casing drive, etc., with good expansibility; 8, standard centralized lubrication system, maintenance more convenient, improve work reliability. Project Unit Parameters Working parameters Maximum drilling diameter mm φ2800/φ2500 * Maximum drilling depth m 103 Engine Parameters Model - QSX15 Rated power kW 373 Power head parameters Maximum output torque kN﹒m 400 Speed r/min 25 July Pressurizing cylinder parameters Maximum pressure kN 300 Maximum lifting force kN 400 Maximum travel m 6 Pressurized hoist parameters Maximum pressure kN 400 Maximum lifting force kN 400 Maximum travel m 18 Main hoist parameter Maximum lifting force kN 370 Max. hoist speed m/min 60 Secondary winch parameters Maximum lifting force kN 100 Max. hoist speed m/min 65 Lateral/forward/backward ° 5/4/15 Chassis parameters Maximum travel speed km/h 1.3 Maximum grade % 35 Track shoe width mm 800 Maximum total width of crawler mm 3500-4900 System parameters Working pressure MPa 32 Whole machine quality t 118 Outline dimension parameters Working status mm 10995 × 4900 × 26640 Transport status mm 20755 × 3500 × 3910

1. One machine has multiple functions, which can realize rapid switching of functions such as oil cylinder pressurization, winking pressurization, pipe rubbing machine, long spiral, double power head, etc., to meet more different engineering construction requirements; 2, the use of rotary drilling rig special H-type hydraulic telescopic crawler chassis, equipped with large diameter slewing bearing, to ensure the super stability and transportation convenience; 3. Optimize the design of the double-boom luffing mechanism, optimize the position of the hinge point, and take into account the stability of construction and the convenience of transfer transportation; 4. The main and auxiliary hoisting adopts single-row rope technology, the life of the wire rope is 2 to 4 times longer than the multi-layer rope, and the use cost is lower; 5. Equipped with Volvo electronically controlled turbocharged engine, which has greater power, strong power and lower fuel consumption; 6. The hydraulic system adopts load sensing technology, superposition of total power control and limit power control technology, so that the hydraulic system is more efficient and energy-saving, and adopts an independent radiator system with high heat dissipation efficiency; 7. The working performance of multi-gear power head and single-row rope main hoisting is improved by 20%, and the working efficiency is higher; 8. The intelligent control system realizes the functions of automatic adjustment and display of the verticality of the drill mast, automatic rotation, automatic soil dumping, automatic lifting and pouring of the long spiral method and pile type display, etc. The bus panel design is adopted to effectively prevent misoperation.

1, special hydraulic telescopic crawler chassis, large diameter slewing bearing, with super stability and transportation convenience; 2. Cummins turbocharged engine adopts advanced electro-hydraulic control technology and has strong power. 3, the front single row rope main hoisting structure, wire rope life is greatly extended, the use of lower cost. 4. A variety of drill pipe configurations are available, which can meet the construction of large-hole deep piles in hard formations, with a maximum drilling depth of 102 meters. 5. Optional multi-function configuration: outrigger cylinder, casing drive. Extensibility is good. 6. The power head has a common mode and a rock-entering mode, which are respectively aimed at soil layer and rock layer operations, thus improving the construction efficiency; 7, standard centralized lubrication system, maintenance more convenient, improve work reliability.

XCMG XR280D rotary drilling rig performance characteristics: 1, special hydraulic telescopic crawler chassis, large diameter slewing bearing, with strong stability and transportation convenience; 2, Cummins turbocharged engine, the use of advanced electro-hydraulic control technology, strong power; 3, rear single row rope main hoisting structure, wire rope life is greatly extended, the use of lower cost; 4. Optional multi-function configuration: outrigger cylinder, casing drive. Good expansibility; 5. The power head is selected into the rock mode, which improves the construction efficiency according to the rock formation operation; 6, standard centralized lubrication system, maintenance more convenient, improve work reliability. Project Unit Parameters Working parameters Maximum drilling diameter mm φ2500/φ2200 * Maximum drilling depth m 88 Engine Parameters Model - QSM11-C400 Rated power kW 298 Power head parameters Maximum output torque kN﹒m 280 Speed r/min June 22 Pressurizing cylinder parameters Maximum pressure kN 210 Maximum lifting force kN 320 Maximum travel m 6 Pressurized hoist parameters Maximum pressure kN 300 Maximum lifting force kN 300 Maximum travel m 16 Main hoist parameter Maximum lifting force kN 300 Max. hoist speed m/min 60 Secondary winch parameters Maximum lifting force kN 100 Max. hoist speed m/min 65 Lateral/forward/backward ° ± 4/5/15 Chassis parameters Maximum travel speed km/h 1.5 Maximum grade % 35 Track shoe width mm 800 Maximum total width of crawler mm 3500-4800 System parameters Working pressure MPa 32 Whole machine quality t 88/96 Outline dimension parameters Working status mm 10770 × 4800 × 23550 Transport status mm 17380 × 3500 × 3540

One machine has multiple functions, which can realize rapid switching of functions such as cylinder pressurization, winking and pressurization, pipe rubbing machine, etc., to meet more different engineering construction requirements; Equipped with Isuzu electronically controlled turbocharged engine, lower fuel consumption, convenient and quick service

XCMG XR180D rotary drilling rig adopts special hydraulic telescopic (TDP series) crawler chassis and large diameter slewing bearing for rotary drilling rig to meet the super stability and transportation convenience."

Technical Characteristics 1.As a multi-functional machine,XR160E can realize the quick switching of functions such as crowd cylinder, crowd winch, CFA and dual rotary drive to meet more different construction needs; 2.Cummins electronically controlled turbocharged engine ensures strong power, convenient and efficient service; 3.With a maximum output torque of 160kN·m and a maximum speed of 35 r/min, the rotary drive can work more efficiently; 4.The main and auxiliary winches both adopt single-row rope technology, The service life of wire rope is 2~4 times longer than that of multi-layer rope and the cost is lower; 5.The parallelogram luffing mechanism with double swing arm has a large support angle and a 24% increase in support range, which makes the operation more stable; 6.The hydraulic system adopts negative flow control technology which has a fast response and good handling performance; 7.The high-power dual hydraulic oil cooler is suitable for construction in high-temperature areas; 8.The intelligent control system can achieve functions such as automatic adjustment and display of mast perpendicularity,automatic slew and spin-off, etc; 9.With a large diameter slewing bearing, the TDP series hydraulic crawler chassis dedicated for rotary drilling rigs ensures better working stability.

XR150 rotary drilling rig adopts imported Cummins turbocharged engine, which has strong power, reliable performance and unique speed control design, making you more fuel-efficient. Retractable special rotary drill chassis, equipped with double box type luffing mechanism, easy to transport and adjust, to ensure the stability and reliability of the work. Imported Kawasaki hydraulic original, power system matching reasonable, high construction efficiency. GPS global satellite positioning system application, the whole machine working conditions to achieve remote data analysis, and has remote real-time monitoring, remote fault diagnosis function.

The SR405R-HK rotary drilling rig adopts the new sixth generation 580 drill pipe, integral pressure table, material upgrade, reinforcement ring and other designs, and the strength is increased by 25%. Strong impact resistance, 15% increase in pressure and 25% increase in rock entry capacity; 5-section machine lock rod hard rock drilling depth can reach 88 meters.

SR360 Ⅲ-SR rotary drilling rig super-large bridge pile foundation construction stability high triangular amplitude structure, compared with the parallelogram structure increased by 12%. Strong construction capacity can achieve the maximum drilling diameter of 5M, drilling depth of 96M. Into the rock adaptive technology torque, speed, pressure automatic matching. The innovative power head has the characteristics of long service life, good cushioning performance, and convenient maintenance. Its power output control technology is perfectly matched with Sany self-made drill pipe, which can increase the life of the drill pipe by more than 10%. Dedicated rotary drilling rig chassis.

Efficient construction Using drilling parameters matching technology and into the rock adaptive technology, torque, speed, pressure automatic matching. Reliable structure The whole machine is equipped with a new box mast, optimized luffing mechanism, and the structural rigidity and fatigue strength are significantly enhanced.